Breathable Laminates

Breathable laminates are multi-layered materials that let air and moisture vapor through while blocking liquids. They are widely used in outdoor clothing, sportswear, and protective gear to keep wearers comfortable and dry. These laminates usually feature a breathable membrane between the outer and inner layers, balancing waterproofing and breathability.

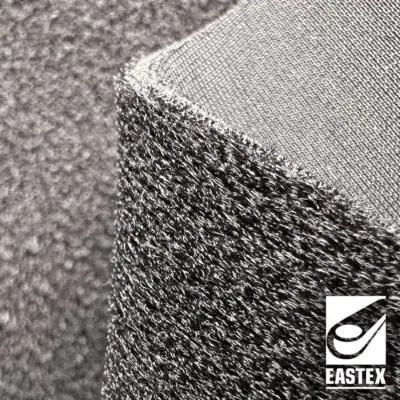

Eastex Products, LLC excels in providing innovative textile solutions, specializing in breathable laminates that guarantee comfort and moisture management. Our extensive product range and commitment to quality make us a preferred partner in the textile industry. Moreover, by continuously advancing our technologies, we remain a leading source of high-performance materials worldwide.

Showing all 5 results