Why Choose Eastex for Custom Lamination?

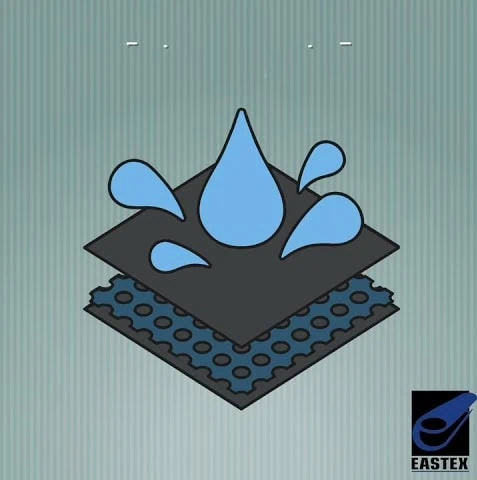

Eastex’s lamination process allows for combining multiple functions into one material, which can simplify product design and reduce the need for additional components. For example, a fabric can be waterproof yet breathable, or soft to the touch while resisting abrasion. This approach helps manufacturers solve material challenges that off-the-shelf fabrics cannot.

The company’s in-house expertise in material selection, adhesive chemistry, and lamination techniques ensures consistent quality. Eastex also offers competitive pricing and can accommodate lower minimum orders, making it easier for clients to test and develop new custom laminate fabrics.

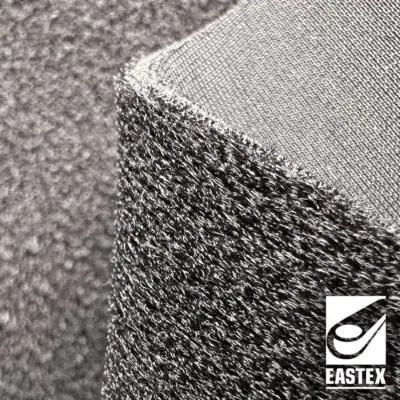

Common Layers and Components

Typical substrates include nylon and polyester woven or knit fabrics, non-wovens, foam layers, and spacer fabrics for cushioning or airflow. Membranes like TPU (thermoplastic polyurethane), PTFE, PVC, PU, or ePTFE are often laminated to add waterproof or breathable qualities. Adhesives are chosen based on the need for flexibility, durability, or chemical resistance and include hot melt, solvent-based, and water-based types.

Key Benefits of Custom Laminates

Custom laminates can deliver a range of functional benefits such as:

- Waterproof and breathable performance to keep users comfortable and dry.

- High abrasion resistance for durability in tough environments.

- Antimicrobial protection for hygiene-critical applications.

- Flame retardancy for safety compliance.

- Sound dampening qualities for noise control.

- Insulation for temperature regulation.

- Non-slip surfaces or enhanced grip.

What Are Custom Laminates?

Custom laminates consist of two or more fabric or film layers permanently bonded together. These layers may include woven or knit textiles, foam, non-woven materials, or barrier films. Through lamination, each component’s properties are combined, resulting in a composite material that can protect, breathe, stretch, or resist fluids, depending on the layers selected.