Slip-Not Fabrics

When reliable grip and slip resistance are critical, Eastex Products’ Slip-Not fabrics offer a dependable solution. These high-performance anti slip fabrics are engineered to maintain traction across various surfaces and conditions—wet, dry, or oily. Developed with a focus on durability, Slip-Not helps prevent slippage and shifting in products used across industries such as healthcare, safety, marine, and transportation. Each fabric is created with a specialized coating that delivers both strong grip and wear resistance, making it ideal for use in settings where safety and product stability matter.

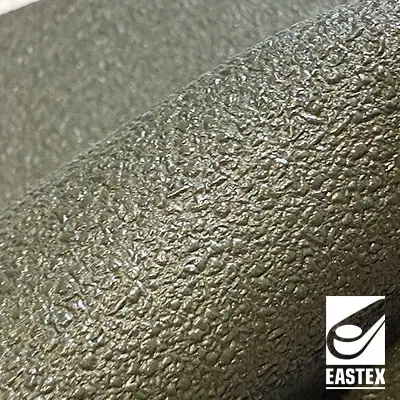

Slip-Not fabrics are made from knit or woven substrates that are coated with PVC or polyurethane to create a surface texture with high grip properties. The coating is applied in various embossed patterns such as dots or pebbles, depending on the required level of traction and visual preference. These fabrics are engineered to hold their position under friction and pressure, making them effective for a wide range of applications. The materials are available in multiple finishes, colors, and thicknesses to meet different manufacturing needs.

Showing all 11 results