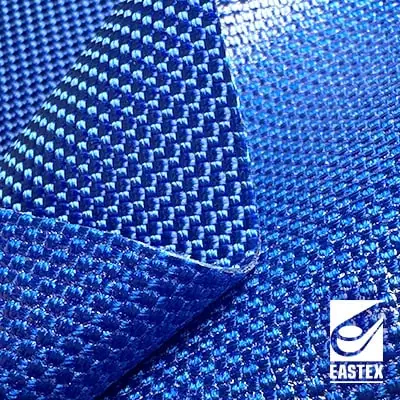

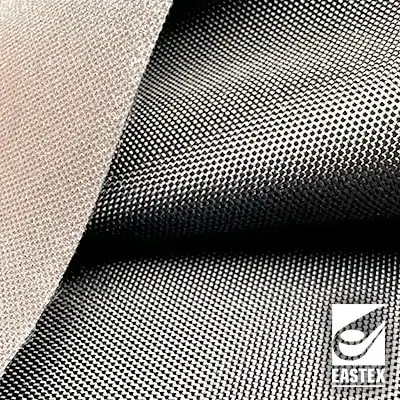

Coated Woven Fabrics

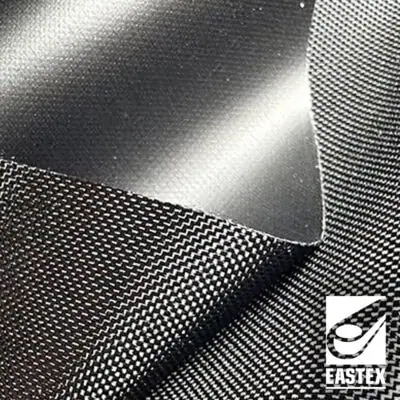

Eastex coated woven fabrics offer the inherent strength and stability of woven substrates, significantly enhanced by specialized coatings. This combination creates highly durable, functional textiles with properties such as superior water resistance, abrasion resistance, improved aesthetics, and tailored breathability.

From rugged outdoor gear to critical industrial components, our coated woven fabrics deliver robust performance designed for demanding environments.

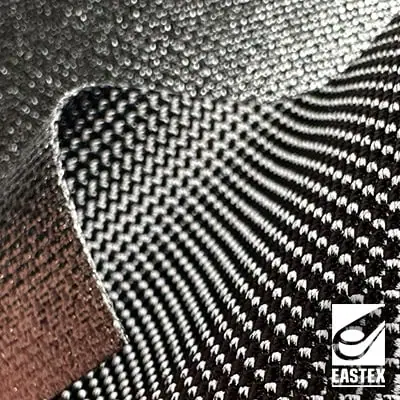

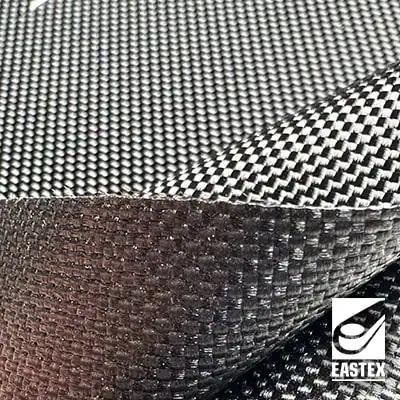

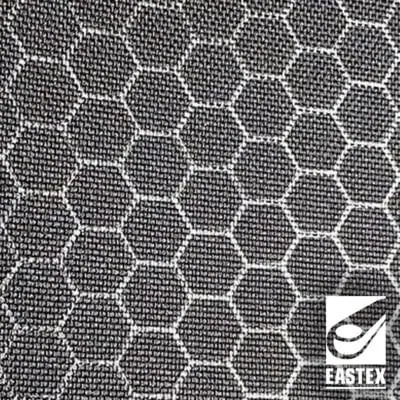

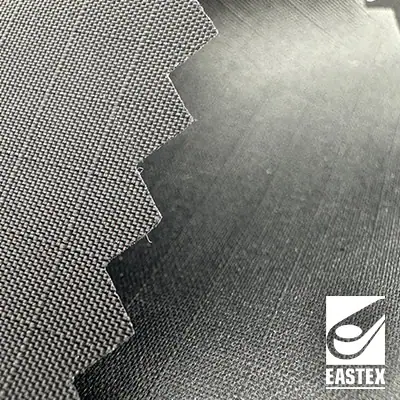

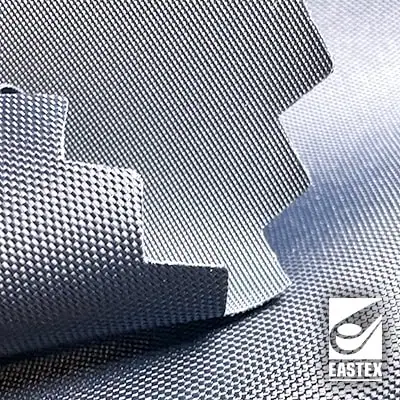

Coated woven fabrics can be best understood by breaking down their two core components. At their foundation lies a woven structure—interlaced yarns designed to deliver strength, dimensional stability, and structure. These woven bases bring valuable qualities such as breathability and durability. However, it’s the applied coating that elevates their functionality.

Various coatings—including polyurethane (PU), polyvinyl chloride (PVC), silicone, fluorocarbons, and others—can be layered onto the fabric surface to introduce specialized performance features. Depending on the coating used, properties like water resistance, chemical resistance, flame retardancy, or flexibility can be achieved, making coated woven fabrics highly versatile across countless industrial and commercial applications.

At Eastex, we offer several different forms of coating, including knife coating, roll coating, hot meld extrusion and more.

Showing all 14 results