What Are Stretch Fabrics?

Stretch fabrics are engineered to elongate and return to their original shape, providing flexibility, comfort, and a custom fit. Used in everything from apparel to industrial applications, these materials adapt to movement and performance needs.

Key Characteristics

- Elongation and Recovery Designed to stretch with motion and return to their original dimensions.

- Enhanced Comfort and Fit Ideal for wearables and products that benefit from flexibility.

- Versatile Applications Used in clothing, accessories, upholstery, and technical products.

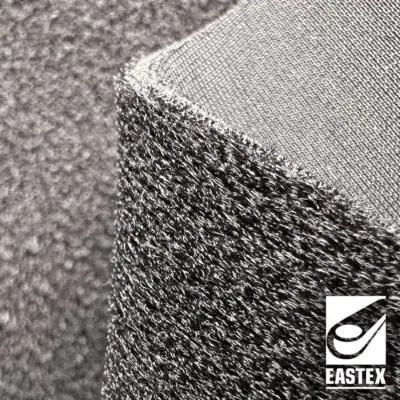

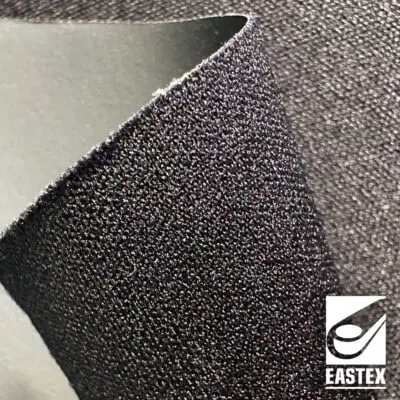

Types of Stretch Fabrics

Two-Way Stretch

- Stretches in one direction (either lengthwise or widthwise).

- Provides moderate flexibility and is commonly used in structured garments and upholstery.

Four-Way Stretch

- Stretches in both directions (lengthwise and widthwise).

- Offers maximum mobility, making it perfect for activewear, performance gear, and ergonomic applications.

Specialized Processes in Stretch Fabric Manufacturing

The stretch properties of a fabric result from several key factors, each contributing to its flexibility and performance:

- Fiber Content Stretch fabrics often incorporate elastomeric fibers like elastane, PBT, or Lycra®, which deliver built-in elasticity and allow the fabric to extend and recover with ease.

- Knit or Weave Structure Specific knitting and weaving methods—such as rib knits or tailored woven patterns—are designed to promote stretch, even without high elastomeric content.

- Mechanical Stretch In some cases, stretch is achieved without any elastic fibers at all. Instead, crimped fibers or textured yarns are used to create a mechanical stretch effect through the fabric’s structure alone.

Benefits of Stretch Fibers

Stretch fibers offer a range of valuable performance benefits that make them ideal for numerous applications. Key advantages include:

- Enhanced flexibility and freedom of movement Stretch fibers allow garments and products to conform comfortably to body shapes or contours, improving wearability and range of motion.

- Shape retention They help maintain a product’s form, even after repeated use or stretching, reducing sagging or deformation over time.

- Improved fit and comfort Whether used in apparel, upholstery, or gear, stretch fabrics provide a snug yet accommodating fit that adapts to various body types or structural demands.

- Durability under stress These fibers can endure tension and repeated stretching without losing their structural integrity, making them ideal for activewear, performance gear, and medical applications.

- Design versatility Stretch fibers enable designers to create streamlined, close-fitting silhouettes or adaptive solutions that respond to movement or pressure.